Polycarbonate gazebos are inexpensive and interesting designs suitable for equipping private house areas or decorating parks. What are the arbors made of polycarbonate, their positive qualities and shortcomings, how to make the basis of various materials - read on.

Advantages of Polycarbonate Pergolas

- The gazebo made of polymer materials has several advantages:

- Low weight. This means that it is not necessary to build a foundation for the construction. The structure can be mounted anywhere, and if necessary, move it, dismantling only part of the gazebo.

- The possibility of self-construction. Of course, today you can buy any version of the gazebo. But making it yourself is much more interesting. So you can show individuality and take into account all the territorial nuances.

- Inexpensive material. In addition, the frame does not require the use of expensive profiles.

- You can combine and make your own design. Polycarbonate blends perfectly with many materials.

- As a separate material, polycarbonate has more than one advantage:

- easy to cut and drill;

- bends freely both along and perpendicularly;

- maintains high and subzero temperatures and its differences;

- strong enough;

- can be operated in regions with a humid climate;

- not flammable;

- does not need additional processing;

- Warranty period is 20 years.

Additionally, polycarbonate is best suited for light-transmitting structures. It is particularly resistant to ultraviolet and perfectly transmits sunlight.

Important! If hail often falls in the region, the structure of cellular polycarbonate should be abandoned.

Types of Polycarbonate Arbors

Before decorating a summer cottage with light architecture, you need to decide on the models and functional load of the structure.

And the building itself can be diverse and is classified according to the following criteria:

- Type of construction. There are protected and open buildings. Any kind will decorate a private house. Open erect for recreation only in the warm season. If you plan to rest in bad weather, then choose the closed option.

- By type of installation. Separate mobile and fixed. The last option is being erected on the foundation, so it will be possible to move it. The portable version is suitable for those who prefer constant changes on the site.

- By complexity. There is a simple, easy and compound canopy. When building a simple version, special efforts are not required. When constructing a complex gazebo, you will have to spend a lot of effort, time and money. But such models are durable and can perfectly complement the overall design (house, garden, alpine slides).

- According to the degree of equipment. Can be equipped with a fireplace or barbecue. A simple option is suitable for ordinary tea drinking. If you plan to collect guests at the cottage, then it is better to build a canopy with barbecue.

- According to the degree of operational load. There are models with additional and artistic functions.

- In the form of construction. The garden house can be round, square, oval, straight or polygonal.

Project drafting

After the shape of the gazebo is selected, the phased process of its construction begins. First of all, the project is being developed. One of the main tasks is choosing a place. Also, construction requires preparatory measures to clean the site.

Did you know? Monolithic polycarbonate was invented in the mid-60s. last century. Then it was used mainly in the space and defense industries.

This takes into account how the yard will look and a number of important points:

- wind mode;

- the location of trees and bushes, as well as the shadow of them;

- the degree of unevenness of the soil;

- are there bevels, or is the place predominantly flat.

Before work on the construction of the building, you should sketch the drawing and think over the following points:

- total weight of the structure;

- level of difficulty;

- type of structure;

- design;

- dimensions of the structure;

- if a closed building is planned, think over the ventilation scheme;

- the roof is separately designed: dimensions, structure, tilt angle, material, height;

- reception of the construction of walls, for a building with a fireplace or a barbecue, they plan laying bricks with a listing of sizes;

- wiring diagram and water supply.

Only after calculating all the details and subtleties can you select the material for the manufacture of the base. The more detailed the project is completed and the calculations are made, the easier it will be to build a gazebo.

Only after calculating all the details and subtleties can you select the material for the manufacture of the base. The more detailed the project is completed and the calculations are made, the easier it will be to build a gazebo.

How to make a gazebo on a frame

The frame is the main building element. The load on the weight of the roof, wind, snow mass falls on it. The operation of the entire building depends on the reliability of this element.

Did you know? Polycarbonate glasses lenses are 10 times stronger than other inorganic materials and 200 times stronger than glass. Such glasses are considered the most reliable and non-traumatic in the world.

From profile

A sufficiently strong material is the profile and will serve as a basis for more than one year.

To install such a gazebo you need to take:

- crushed stone and sand for flooring;

- self-tapping screws;

- sealant;

- concrete;

- metal rolling (profile pipe);

- primer;

- fittings;

- polycarbonate sheets;

- level;

- electric drill;

- a shovel;

- apparatus for electric welding;

- grinder;

- a saw for metal;

- fasteners.

The installation process of the canopy includes such works:

- Layout of the site, determining the place for support. Dig holes in the depth of 80-100 cm and in diameter up to 10 cm.

- A layer of 20 cm is lined with sand and gravel.

- Using the level, a profile is set (in the context of 80 × 80 mm and a thickness of 3 mm) and spacers are made for it. Then everything is concreted. If you plan to install a barbecue or fireplace, the thickness of concrete is at least 40 cm.

- After concrete hardening, in 2 days, the lower binding of a horizontal position is carried out. Metal products of a smaller section are welded to supports at a height that allows you to comfortably enter the gazebo.

- Metal “heels” are welded to the profile, and logs are fixed on them with bolts.

- Details of the upper harness are welded to the supports.

- A roof frame is created on a flat surface. Already in finished form, it is welded to the base.

- Metal elements are treated with an anti-corrosion compound.

- The flooring is done. You can use the fill or masonry tiles.

- Polymer sheets are cut according to the drawing and fixed to the base with self-tapping screws.

- The joints are treated with sealant.

Video: Installation of a canopy from a profile

From metal

The metal base is strong and reliable. To prepare such a structure, a rolled profile and pipes are used.

Did you know? Ancient builders put into practice the most unusual materials for modern man. For example, in Africa today you can find buildings, for the construction of which rock salt was used.

The construction process itself consists of the following stages:

- support equipment;

- laying of the lower belt and flooring;

- manufacturing of the upper element and fences;

- fastening polymer sheets.

If the project is designed and metal is selected for the frame, then they take care of the availability of such materials:

- metal pipes (50 mm);

- corner (40 × 40 mm);

- self-tapping screws for metal, brackets;

- wooden flooring or concrete for the floor;

- polymer sheets and accessories for their fastening;

- sealant.

For the construction you need such a tool:

- apparatus for welding;

- soil drill hammer;

- jigsaw;

- hammer;

- saw for cutting polycarbonate;

- building level;

- saw for metal;

- pliers;

- screwdriver.

After the marking, the places for the supports are determined. Then perform such work:

- Holes are drilled in the soil to a depth of 700-1000 mm and across 100 mm.

- The bottom of the pit is lined with sand and gravel.

- Pipes are lowered into the recesses by level. Pre-produce the laying of supports. Concreted.

- After the concrete has dried, they begin to lay the lower belt. Corners are welded to the racks. They install a beam and a wooden floor.

- To fix the beam in the corner, make a hole and fix it with bolts.

- Transverse brackets are welded to the supports for mounting fences.

- Then make the upper belt. It must be durable, since a roof will be installed on it.

- On a straight surface, rafters and overlapping components are welded. They are lifted to the base of the roof and welded to the pillars of the support.

Video: Mounting the frame of the arbor from metal

After the construction of the frame of the upper part and the walls, staining with compositions with anti-corrosion elements is performed.At the end, polymer sheets are fixed. They are pre-cut to the desired pattern. At the same time, the roof can be covered with the same polycarbonate, as well as with any roofing material (slate, decking, etc.).

To fix the polymer in the metal corner, holes are made. Then the screws fix the sheets. At the same time, it is necessary to ensure that they do not press the sheets too tightly. Special plastic profiles are used to connect the material. To ensure impermeability, the joints are treated with silicone.

Did you know? Cellular polycarbonate was invented in Israel specifically for the construction of greenhouses. It was this material that allowed the country to sharply achieve increased yields and receive the title of "oasis in the desert."

From wood

The cheapest base for small polycarbonate architectural structures is wood. The main advantage of the material is ease of use, environmental friendliness, safety, accessibility. At the same time, such a design can be built without special skills and knowledge.

When creating the foundation you will need:

- profiled or glued timber with dimensions of 10 × 10 or 15 × 15 cm;

- logs rounded 15–20 cm;

- ordinary log;

- edged board 40 mm;

- polycarbonate and components for fixing it;

- crushed stone and sand;

- roofing material;

- polymer cutting saw;

- building level;

- hammer;

- shovel;

- screwdriver.

To begin with, build a columnar foundation:

- According to the scheme, markup is carried out.

- A hollow of 500–700 mm deep is dug.

- The bottom of the pit is filled with a layer of sand and gravel. Density - 50 mm.

- In the recesses, wooden supports pre-treated with an anti-corrosion composition are installed. Part of the rack, which will be located in concrete, is wrapped with roofing material to increase the waterproofing qualities. Each rack is mounted clearly in level. Poured with concrete.

- After laying the concrete mixture, a temporary support is installed on each rack. This will allow them to be fixed so that they do not move to the side.

During the period of solidification of the building mixture, it is periodically watered with water. It should not be poured - just slightly moistened.

When the base dries, build a frame:

- To obtain a solid structure, the beam is installed horizontally.

- If the structure provides auxiliary support pillars for the roof, they are also installed at this stage.

- The board is treated with an anticorrosive solution and fixed to the floor with self-tapping screws.

The next stage is the sheathing and construction of the roof. An example of a simple single-pitch construction:

- From a beam with a cross section of 100 × 100 mm, an upper strapping is installed.

- At the ends of the racks make cuts. In them, then a strapping beam will be installed, which will connect all the supports. It is attached at an angle with self-tapping screws. To prevent a split, pre-drill holes.

- Bearing rafters, crates are made and the polymer is fixed.

Important! The disadvantage of wood is poor water resistance, combustibility, susceptibility to decay, damage by fungi, rodents and mold. Therefore, the wooden structure must be constantly treated with special impregnations.

After finishing work, the structure is varnished.Wall cladding depends on the nature of the gazebo. If an open structure is conceived, then it is enough to make a railing and then install furniture. If a closed form is chosen, then for small buildings, polycarbonate is simply fixed to the supports. When fixing the polymer, the sheets are laid vertically so as not to provoke the collection of moisture inside.

Gazebo decoration

At this stage, they carry out the installation of all parts and the design of the internal space. Inside, the building can be equipped with a table, benches, flowerpots, shelves, bar, hammock, hanging chair and other attributes. The main condition is good quality materials.Cozy arbor will give textile products. Plain or multi-colored curtains in each individual section will create their own atmosphere.

The exterior design consists of:

- painting and varnishing of wooden wall parts;

- equipment of beds;

- garden path constructions;

- installation of lights.

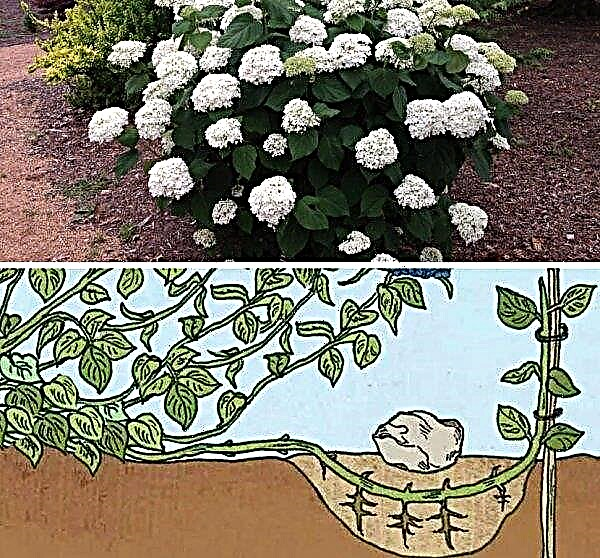

Everyone can show imagination in decorating the gazebo. For example, an open structure can be “drowned” in curly flowers (hops, grapes, honeysuckle). Containers with petunia on the railing or flowerpots with annual flowers hanging around the perimeter look good.

Important! Since the summer version of the canopy is not heated, temperature fluctuations and high humidity can damage furniture.

Whatever frame is intended for a polycarbonate gazebo, it will undoubtedly decorate the garden. And if the area allows, you can show your imagination and create a real architectural masterpiece.